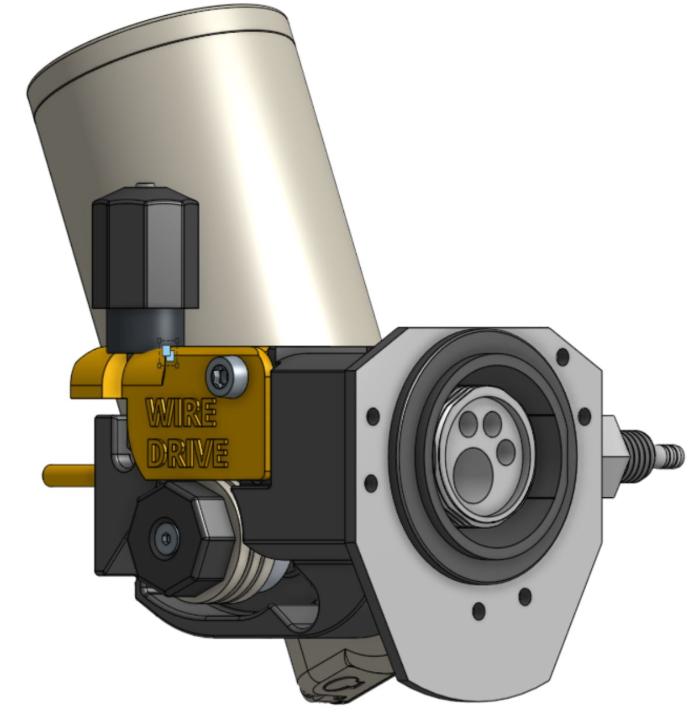

2-Roll Wire Drive

The 2-Roll Wire Drive is a compact wire drive unit with integrated torch adapter and front protection. The welding current is connected at the back of the torch adapter.

The main feature of the 2-Roll Wire Drive is the compact design and its small weight, ideally suited for robotic-based welding applications. The Wire Drive can be installed fast, fixed by three screws or pop rivets at the front side.

The feed rolls are available in the diameter of 30 mm or 36 mm and are reversible for two different wire diameters.

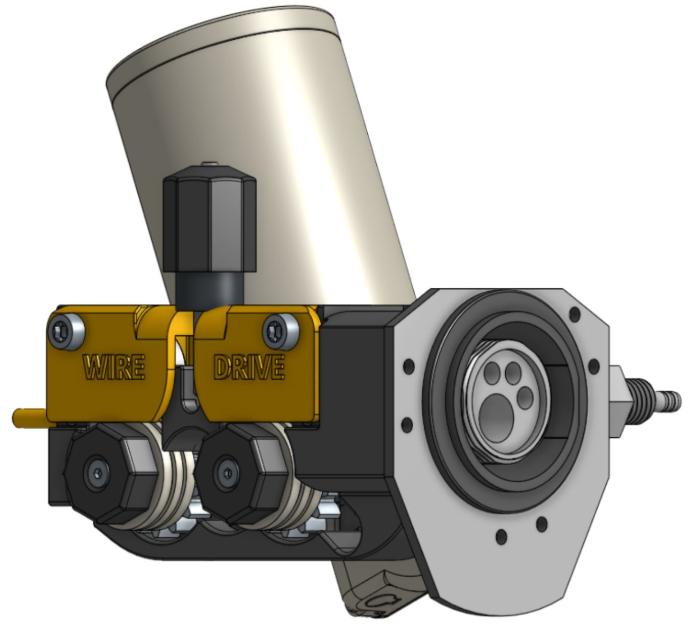

4-Roll Wire Drive

The straight 4-Roll Wire Drive is flexible, light weight and compact. The compact design and weight is ideally suited for robotic-based welding applications. The Wire Drive can be installed fast, fixed by three screws or pop rivets at the front side.

The feed rolls are available in the diameter of 30 mm or 36 mm and are reversible for two different wire diameters.

The motor with gearbox is adjusted from the rear side, in vertical position.

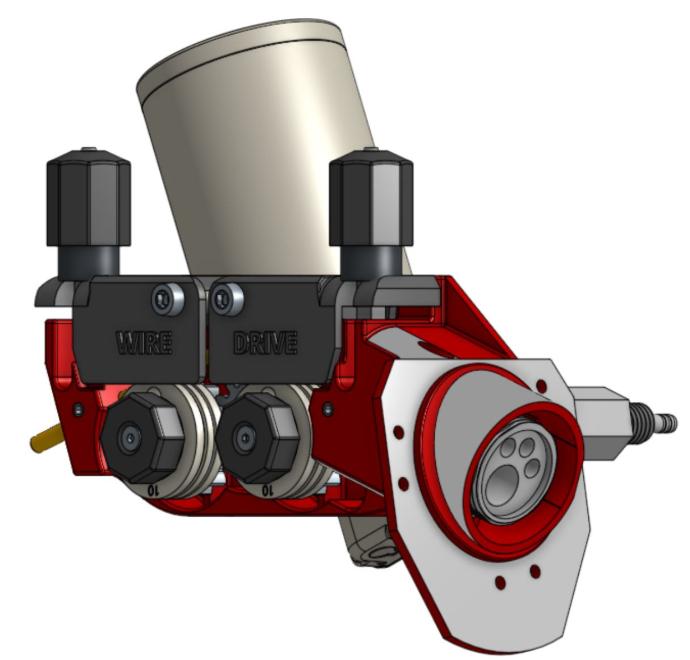

Revolution

Bended wire guiding Technology

The bended wire guide Technology, bending the wire in the Wire Drive, is revolutionary in wire drive technology. The inclination of the torch is selected at an ideal downside angle of 30°. The torch adapter is integrated including front protection.

To adjust the connection angle of the welding torch cable to the natural angle, defined by the torch cable bundle will deliver an improved wire feeding with less erratic speed variance. This technology is the Protected industrial design No. DM/222915 of WireDrive AG.

Efficient Assembly

Assembly time is reduced by 5 to 6 minutes with our solutions.

The Wire Drive unit is fixed with two screws. The unit can be placed at the bottom of the wire feeder cabinet or on the side of the vertical middle plate within the wire feeder cabinet.

Less parts and lower variation are reducing purchasing and inventory cost and simplifying logistics.

The welding current is directly connected to the integrated torch adapter.

Customized Design

We are prepared to produce customer designed Wire Drives.

Our user-centered design is allowing to adjust to your design language. This will position you to convince with a consistent product family.