WireDrive @ Tradeshow

Thank you for visiting us in our booth at the Schweissen&Schneiden Fair 2025 in Essen. We could learn a lot by listening to your experience. We gained new insights and received valuable feedback.

Let's discuss your requirements! Request a PolyDrive prototype for testing or receive:

• Detailed data sheets

• 3D models (STEP/IGES)

• Individual on-site

Contact: andreas.koch@wiredrive.ch

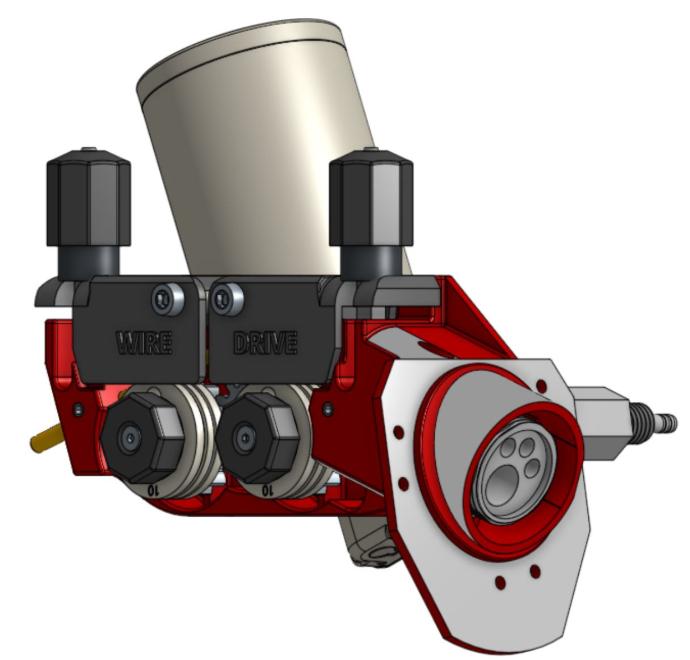

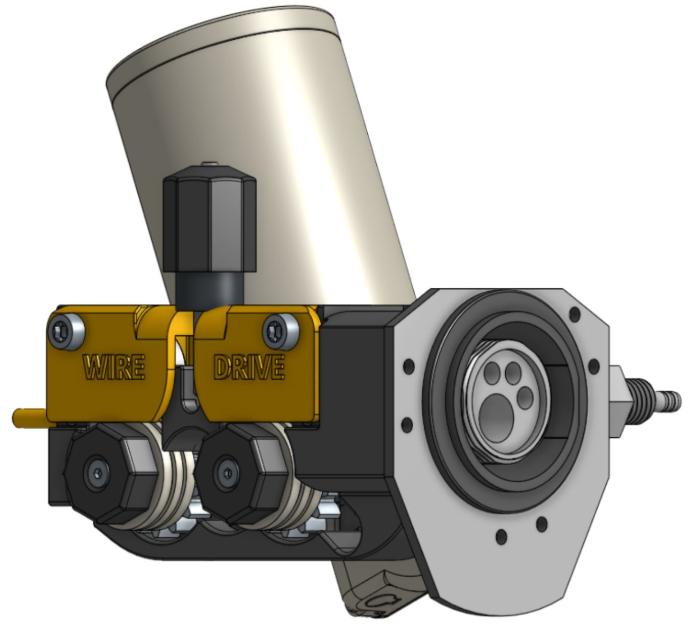

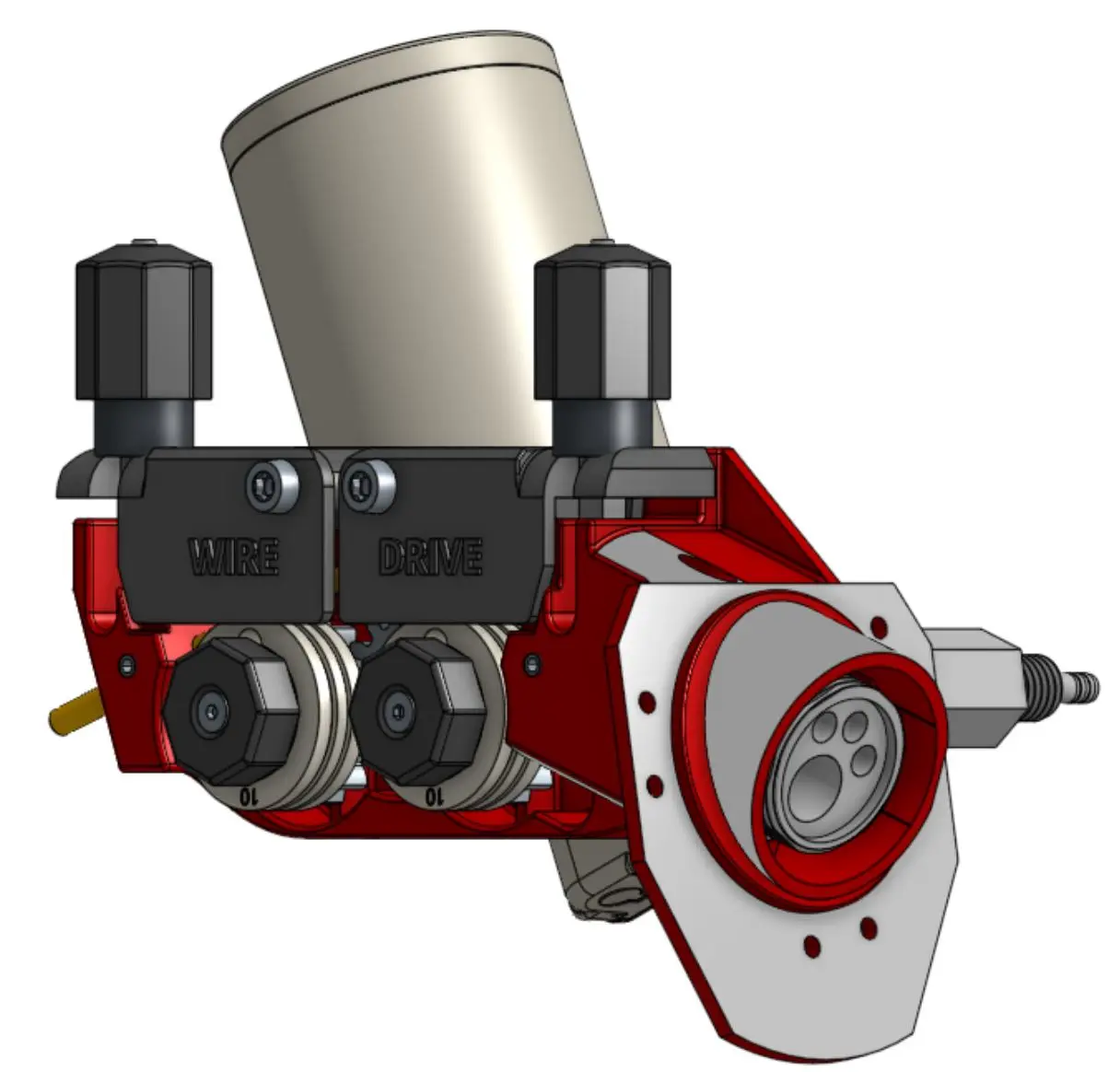

REVOLUTION in Wire Feeding

with Swiss Technology

You need precise, reliable and powerful wire drives on a high level of quality and professionalism. The wire drive shall feed the welding wire at constant speed in workshops and in harsh environment with substantially less erratic speed variance for any position of the welding torch.

Superior quality welding differentiates with two distinct competitive advantages: weld integrity and welding repeatability. Reliable welding machines are delivering consistently strong, durable welds free from cracking, distortion or other porosity.

Our solution will deliver.

Innovative Solutions

WireDrive AG represents the experience in welding technology of more than 40 years . Our aim is to deliver a complete portfolio of Wire Drive and Coaxial Cable products for industrial applications. We develop our products from the concept idea to the final product in our company. Our innovative technology is the answer to your needs and challenges. Our technology suits your needs by providing advanced operational characteristics. Superior operator safety is a key element underlying all our solutions.

The combination of innovative ideas with high quality components will improve the stability of the wire speed in every environment and operational situation. This is the base to further improve your welding quality.

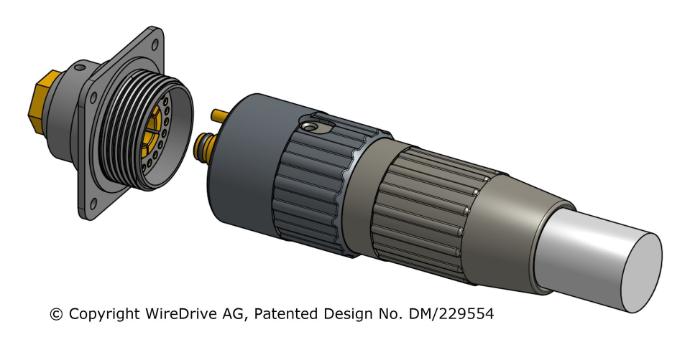

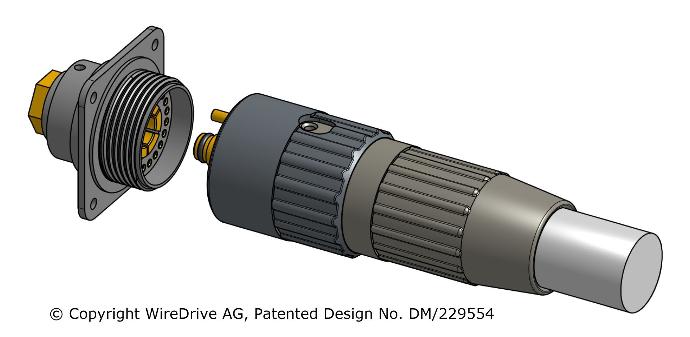

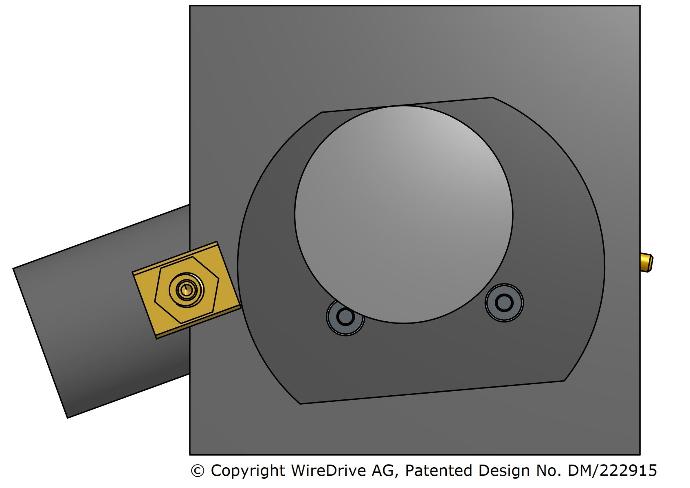

Coaxial Welding Cables

Modern welding machines require an increasing number of signal wires for communication between the power source and the wire feeder. Our innovative and very robust combined coaxial welding cable provides enough signal connections for advanced needs. Separate connectors for the signal cable are no longer needed, saving space as well as material and assembly costs.

The patented design of the cable system is very suitable for harsh environmental conditions.

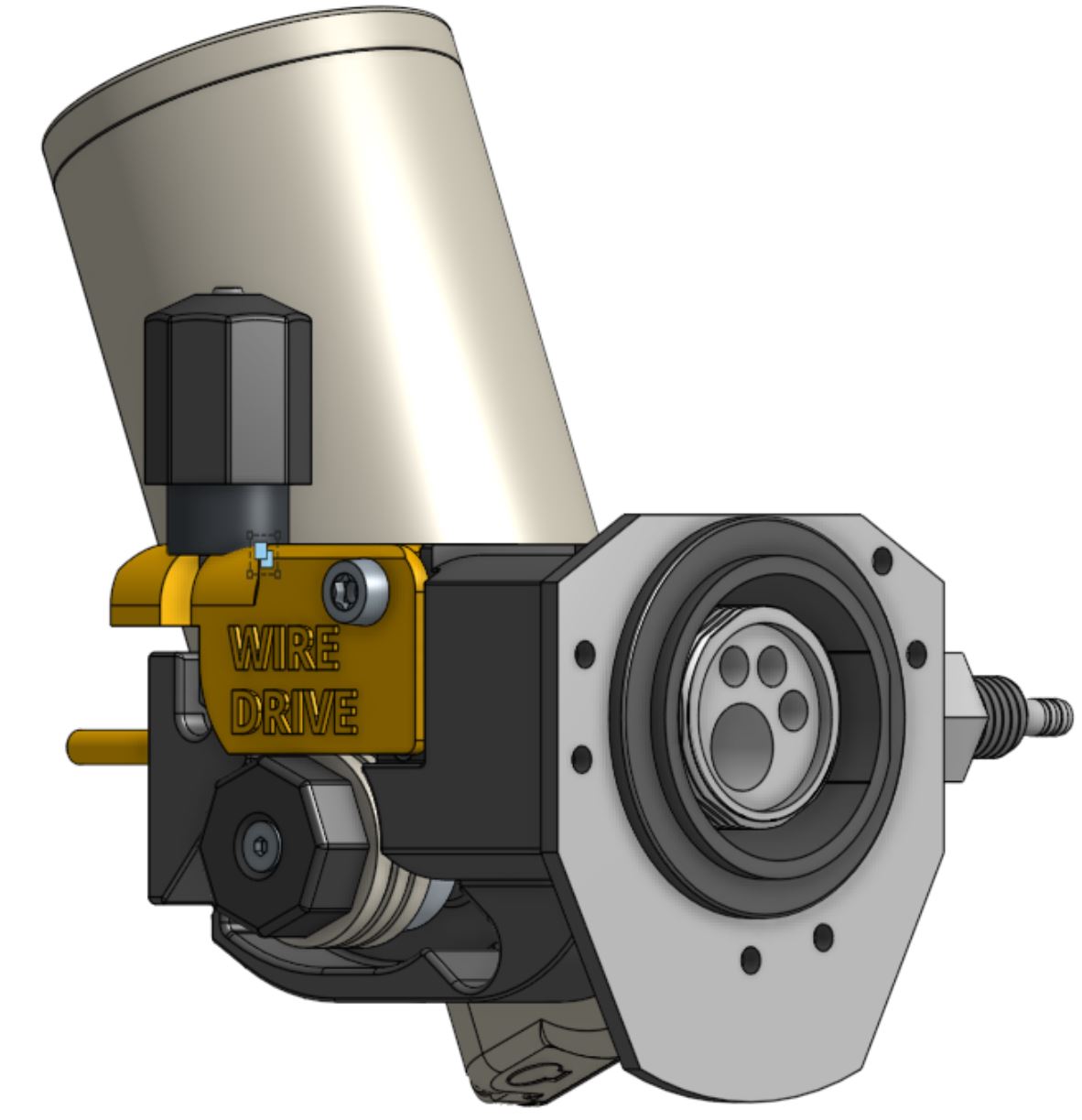

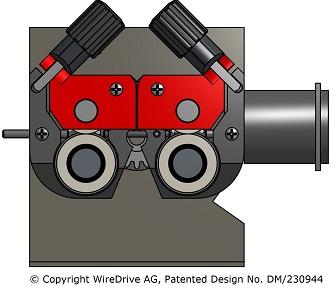

Safety by Design

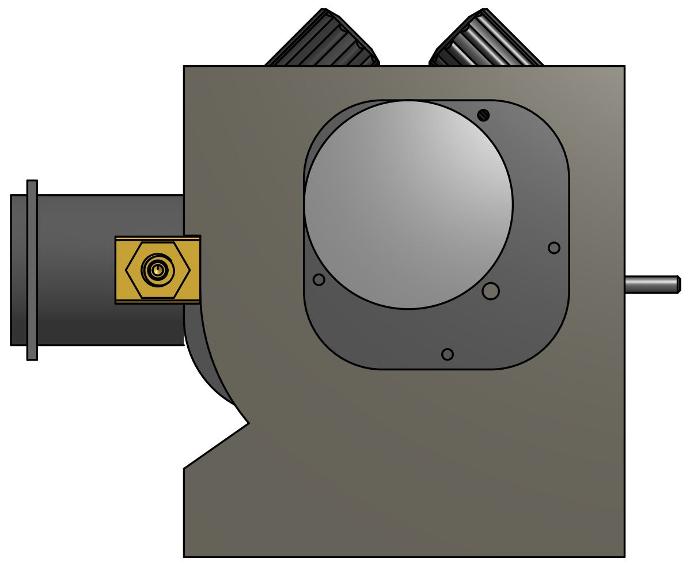

Safety of the operator is an important decision criteria. The drive gear is located on the back side, fully covered by the Wire Drive. The feed rolls are fitted from the front side, reversible for two wire diameters.

The shaft of the feed rolls and drive gears are mounted on bronze bushes and optionally onball bearings . The ball bearings will deliver long lasting reliable operation at low noise levels.

The motor is driving the central gear directly from the rear side of the WireDrive.

Advanced Operation

Superior Safety

Swivel technology

Self-lifting pressure arms

Pressure adjustment

Efficient Assembly

Time saving in assembly

Integrated torch adapter

Integrated front protection

Isolated

Customer Service

Spare parts concept

Online spare parts identification